In today's industrial and maritime environments, safety is paramount—especially when it comes to lifting equipment such as cranes, davits, lifeboats, and hoists. Verifying the strength and reliability of this equipment before use is a critical step that can prevent accidents and save lives. Among the most efficient tools used in this process are load test bags. These flexible, water-filled containers are rapidly replacing traditional solid weights for load testing, thanks to their numerous advantages.

One of the most significant advantages of load test water bag is their portability. Unlike bulky and heavy steel weights that require cranes or forklifts just to move, load test bags can be folded and easily transported to testing sites. When empty, they are lightweight and compact, saving space and reducing transportation costs. This is particularly valuable in offshore and remote locations where access to heavy machinery is limited.

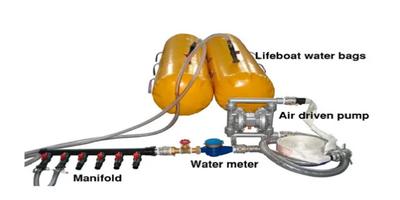

In addition, setting up load test bags requires minimal manpower. They can be carried to the test site by hand, connected to a water source, and gradually filled to the required load—making them ideal for temporary or mobile operations.

Another major benefit of load test bags is their ability to provide precise and controlled loading. Since the bags are filled with water incrementally, the load can be gradually increased and monitored in real time using load cells or digital gauges. This allows for better control during the testing process and reduces the risk of sudden overloads, which can cause damage or failure.

Controlled filling also enables operators to stop the test at any stage if structural issues are detected, improving safety and reducing the likelihood of accidents. This precision is especially useful for testing lifeboats, winches, and davits that require compliance with strict safety regulations.

Using load test bags is significantly more economical over time compared to traditional weights. The same set of bags can be used repeatedly for multiple applications, across various sites and equipment. The only material cost during operation is water, which can often be sourced directly from the environment or reused from previous tests.

Furthermore, load test bags minimize labor and equipment costs associated with transporting and storing solid weights. Their reusability and low maintenance make them a smart investment for companies conducting frequent load testing.

Load test bags offer a safer testing environment for operators. Since the weight is applied slowly and predictably, the chance of mechanical failure due to sudden shock loading is significantly reduced. Their design typically includes overpressure protection valves and heavy-duty lifting straps that are engineered to withstand high stress.

In the event of an emergency or unexpected failure during the test, the water can be quickly drained, instantly reducing the load. This added level of control is a key safety advantage that fixed weights cannot provide.

Whether you're testing a crane on a construction site, a davit on a ship, or an overhead beam in a warehouse, load test bags can be adapted to meet your specific needs. They come in various capacities—from a few hundred kilograms to several tons—and can be configured for vertical, horizontal, or multi-point loading scenarios.

Their versatility makes load test bags suitable for a wide range of industries, including shipping, offshore drilling, aviation, mining, and infrastructure. This flexibility allows companies to streamline their testing processes without having to invest in separate equipment for each application.

| Feature | Description |

|---|---|

| Portability | Foldable and lightweight when empty, making them easy to transport and ideal for remote locations. |

| Easy Handling | Requires minimal manpower; can be set up quickly with just a water source. |

| Precision & Control | Allows gradual water filling with real-time monitoring to ensure accurate and safe load testing. |

| Cost-Effectiveness | Reusable over many tests; water is the only material cost, reducing operational expenses. |

| Safety Features | Slow, controlled loading and built-in safety components minimize risk during testing. |

| Versatility | Suitable for cranes, davits, lifeboats, beams, and more, across various industries and applications. |

For organizations seeking high-quality, durable, and certified load test bags, choosing the right supplier is essential. Matchau is a trusted name in the industry, known for producing robust and reliable load test bags that meet international safety and performance standards. Whether you're testing lifeboats, cranes, or lifting beams, Matchau's expertly engineered solutions provide peace of mind and long-term value.