Pilot ladders and embarkation ladders are two different types of marine ladders, each with particular design features and operational uses essential for vessel safety.

Pilot Ladder:

The pilot ladder is a specialized ladder used exclusively for the transfer of ship pilots boarding or leaving a vessel. Pilots assist with navigation through difficult waters such as harbors or canals. Unlike regular boarding ladders, the pilot ladder’s construction follows strict international standards to ensure pilot safety during transfer even in rough sea conditions.

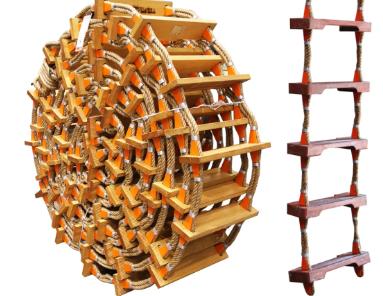

Structurally, pilot ladders feature wooden steps (traditionally hardwood) attached to two strong ropes. A distinctive feature is the inclusion of spreader bars—long horizontal steps placed at fixed intervals to prevent the ladder from twisting or tangling when hung vertically against the ship’s hull. This design provides a safe and secure means for pilots to climb aboard, minimizing slip or entanglement risks.

Embarkation Ladder:

Embarkation ladders, on the other hand, are generally used for crew or passenger boarding and disembarking under calmer conditions, such as when vessels are alongside docks or in harbors. These ladders are usually simpler rope or wire ladders without spreaders, often with wooden or plastic steps.

Unlike pilot ladders, embarkation ladders are not intended for pilot transfer and are primarily a means to reach life-saving appliances (LSA) or escape routes in emergencies. The construction tends to be traditional—often using manila ropes and hardwood steps—but lighter and less complex than pilot ladders. Embarkation ladders usually do not extend as long as pilot ladders since they are deployed for shorter height climbs.

Pilot Ladders:

Pilot ladders must meet detailed international safety standards designed to handle dynamic, often challenging conditions at sea. The ISO 799-1:2019 standard governs the construction, materials, and dimensions of pilot ladders. Additionally, the IMO SOLAS (Safety of Life at Sea) convention mandates strict requirements on their safety features.

Key requirements include:

Rigid wooden steps of specific dimensions and spacing, made typically of durable hardwood or approved aluminum to resist wear and environmental exposure.

Spreader bars every six steps to maintain ladder stability and prevent twisting, which is crucial to safe ascent and descent.

Use of UV-resistant polyester ropes or traditional manila ropes meeting strength and durability standards.

Precise step spacing (about 310mm between steps) and step width for footing and balance.

Certification and type approval from recognized bodies such as classification societies (e.g., CCS, EC) to verify compliance.

Because pilots often board vessels that may be rolling or pitching, these standards guarantee that the ladder remains stable and secure during transfer.

Embarkation Ladders:

Embarkation ladders are regulated under the Life-Saving Appliance (LSA) Code requirements (typically Chapter VI) but the standards are less stringent compared to pilot ladders.

The rules specify that embarkation ladders must be:

Made from materials suitable for marine use, traditionally manila ropes and wood or wire and metal/wood steps.

Strength-tested and type-approved for safe crew and passenger use.

Simpler in design, without the requirement for spreader bars.

Constructed to facilitate safe access between vessels and life-saving equipment or fixed points on the ship.

However, yacht or commercial operators sometimes seek lightweight or novel materials like carbon fiber or synthetic ropes. While these may come with type approval certificates, they may not fully meet the exact ISO or SOLAS letter of the law and could be classified as "equivalents" rather than strict compliant ladders.

In such cases, it is essential to check with the vessel's flag State 1 (registry authority) to confirm if these alternative materials or designs are acceptable for that vessel’s operations and trading areas.

[1] A flag state is a country where a company/person registers its commercial and merchant ships.

The ship will follow the regulation of the flag state nation’s maritime law in the open sea and it will also avail different protections and preferential treatments as tax, certification, and security as per the flag state benefits.

Pilot Ladder Use Cases:

Pilot ladders are legally required for pilot transfers wherever fixed gangways or accommodation ladders are unavailable or unsuitable, particularly when ships anchor offshore or when pilots board while the ship is underway.

Used during open sea or port approaches, allowing safe transfer of pilots from pilot boats to the ship’s side.

Required to handle substantial freeboard heights varying by vessel type and loading conditions.

Designed for rough conditions, pitching, and rolling of vessels in coastal or offshore environments.

If the ladder or its materials do not meet the strict standards or the pilot’s expectations, pilots have the right to refuse boarding—a serious operational risk as it may cause delays or denial of port entry, especially if guests or charter clients are onboard.

Embarkation Ladder Use Cases:

Embarkation ladders are generally used under calmer, dockside conditions for routine crew or passenger boarding, or for access to life-saving appliances during emergencies. They are often used:

When vessels are moored alongside docks, quays, or where a fixed gangway or accommodation ladder cannot be installed.

For access between the ship and safety equipment such as lifeboats or inflatable life rafts.

Situations where step height is relatively low and sea movement is minimal.

Embarkation ladders are not suitable substitutes for pilot ladders for pilot transfer due to their simpler design and lack of spreaders.

Knowing the distinctions between pilot ladders and embarkation ladders—and complying with the applicable standards—is essential for safe vessel operation and to avoid operational disruptions. Pilot ladders must strictly follow ISO and SOLAS regulations to provide safe pilot transfer even in challenging marine environments. Embarkation ladders serve more general and emergency purposes with simpler construction and regulations.

Matchau Group offers professionally manufactured, certified marine rope ladders tailored to your vessel’s specific operational needs, ensuring safety, durability, and international compliance for both pilot and embarkation ladders.